工業プロセスで材料を溶解する際、腐食や汚染の問題に対処するのにうんざりしていませんか? もう探す必要はありません。この記事では、あらゆる溶解ニーズに耐腐食性 SiC (シリコンカーバイド) るつぼを使用することの数多くの利点について説明します。

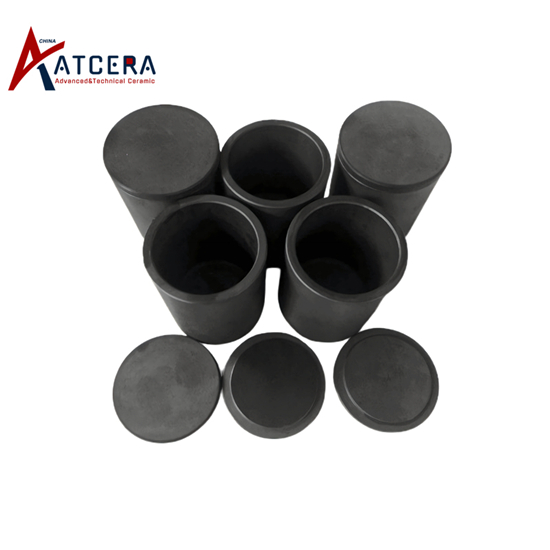

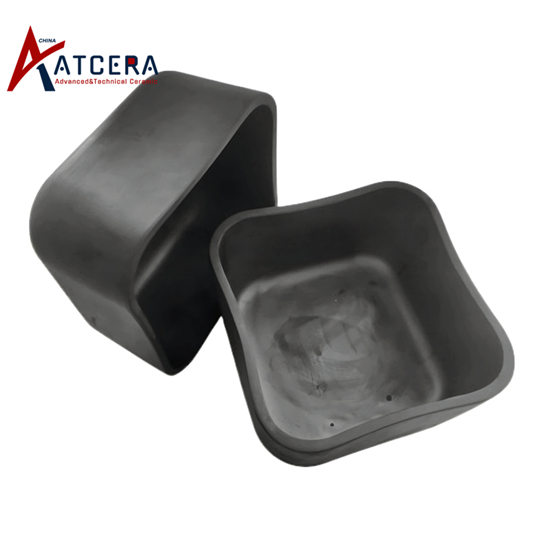

SiCるつぼは、 グラファイトや粘土などの他の材料で作られた従来のるつぼに代わる、耐久性があり長持ちする代替品です。高温、熱衝撃、化学物質に対する優れた耐性を備えているため、さまざまな溶解用途に最適です。金属、合金、セラミックのいずれを溶解する場合でも、SiC るつぼは過酷な条件に耐え、完全性を維持できるため、汚染のリスクが軽減され、最終製品の品質が向上します。

SiC るつぼは、優れた耐性特性に加え、優れた熱伝導性も備えているため、均一な加熱が保証され、ホットスポットの発生が低減されます。これにより、溶解プロセスの効率が向上し、コストが節約されます。

耐腐食性 SiC るつぼを使用する利点と、それが溶解操作にどのような革命をもたらすかについて、さらに詳しく検討します。

るつぼの腐食を理解する

腐食は、材料の溶解や加工において多くの業界が直面する重大な課題です。従来のるつぼは、多くの場合グラファイトや粘土などの材料で作られており、特に高温、強力な化学物質、または腐食性の溶融材料にさらされると腐食しやすくなります。

この腐食は、るつぼの構造的完全性の劣化、溶融材料への不純物の混入、るつぼの頻繁な交換の必要性など、さまざまな問題を引き起こす可能性があります。また、腐食によりるつぼが脆くなり、ひび割れや破損が生じやすくなり、溶解プロセスが中断され、安全上の危険が生じる可能性があります。

るつぼの腐食のメカニズムを理解することは、効果的な解決策を見つけるために不可欠です。溶融材料の化学組成、動作温度、さまざまな反応性物質への暴露などの要因はすべて、腐食の速度と深刻度に影響する可能性があります。これらの根本的な原因に対処することで、業界は溶解操作における腐食に関連するリスクと課題を軽減できます。

耐腐食性SiCるつぼの利点

従来のるつぼ材料の限界に直面して、業界ではより耐久性と耐腐食性に優れた代替品を求めてきました。広く認知されている解決策の 1 つが、炭化ケイ素 (SiC) るつぼの使用です。これらの特殊なるつぼはさまざまな利点があり、さまざまな溶解用途に最適な選択肢となっています。

SiC is a ceramic material that is renowned for its exceptional resistance to corrosion, thermal shock, and high temperatures. Unlike graphite or clay crucibles, SiC crucibles can withstand the harsh conditions encountered in many industrial melting processes, including exposure to molten metals, aggressive chemicals, and extreme temperatures. This enhanced resistance to corrosion and degradation ensures that SiC crucibles maintain their structural integrity and performance over an extended period, reducing the need for frequent replacement.

Moreover, the unique properties of SiC crucibles, such as their excellent thermal conductivity and heat resistance, offer significant advantages in terms of melting efficiency and product quality. By providing consistent and uniform heating throughout the crucible, SiC crucibles help to minimize hot spots and ensure that the molten material is heated evenly, leading to improved process control and better overall results.

Enhanced Durability and Longer Lifespan

One of the primary advantages of using a corrosion-resistant SiC crucible is its exceptional durability and extended lifespan. Unlike traditional crucibles that can quickly deteriorate due to the harsh operating conditions, SiC crucibles are engineered to withstand the rigors of high-temperature melting environments.

The inherent resistance of SiC to chemical attack, thermal shock, and physical wear and tear allows these crucibles to maintain their structural integrity for significantly longer periods. This extended lifespan translates into reduced downtime, fewer interruptions in production, and lower maintenance costs associated with frequent crucible replacements.

Moreover, the durability of SiC crucibles enables them to handle a wider range of molten materials, including highly corrosive substances, without compromising their performance. This versatility is particularly valuable in industries that work with a diverse array of materials, as it allows for a single crucible solution to be utilized across multiple melting processes.

Improved Melting Efficiency and Heat Transfer

In addition to their superior corrosion resistance, SiC crucibles also offer enhanced thermal properties that contribute to improved melting efficiency and heat transfer. The high thermal conductivity of SiC allows for efficient and uniform heat distribution throughout the crucible, ensuring that the molten material is heated evenly and consistently.

This improved heat transfer results in several key benefits. First, it helps to minimize hot spots within the crucible, which can lead to uneven heating and potentially compromise the quality of the final product. By maintaining a more consistent temperature profile, SiC crucibles help to ensure that the melting process is optimized, leading to better control over the material properties and characteristics.

Furthermore, the efficient heat transfer capabilities of SiC crucibles can translate into energy savings for the industrial operation. By requiring less energy input to achieve the desired melting temperatures, these crucibles can contribute to overall cost reductions and improved sustainability in the manufacturing process.

Reduced Contamination and Impurities

One of the significant challenges associated with traditional crucible materials is the risk of contamination and the introduction of impurities into the molten material. This is a critical concern for industries that require high-purity products, such as those in the electronics, aerospace, or medical device manufacturing sectors.

SiC crucibles, however, offer a distinct advantage in this regard. The inherent corrosion resistance of SiC ensures that the crucible material itself does not leach or react with the molten material, minimizing the risk of contamination. This is particularly important when working with sensitive or high-value materials, where even trace amounts of impurities can have a detrimental impact on the final product's performance and quality.

By reducing the potential for contamination, SiC crucibles help to maintain the purity and integrity of the melted material, contributing to improved product quality and consistency. This, in turn, can lead to increased customer satisfaction, reduced waste, and higher overall process efficiency.

Cost Savings and Return on Investment

While the initial investment in a SiC crucible may be higher compared to traditional crucible materials, the long-term benefits and cost savings can make it a highly attractive and cost-effective solution.

The extended lifespan of SiC crucibles, as discussed earlier, translates into fewer replacement costs and reduced downtime associated with crucible failures. This, in turn, leads to a lower overall cost of ownership and a better return on investment over the life of the crucible.

Additionally, the improved melting efficiency and reduced energy consumption of SiC crucibles can contribute to significant cost savings in the manufacturing process. By optimizing the heating and melting operations, industries can benefit from lower energy bills and improved overall process sustainability.

Furthermore, the reduced risk of contamination and the improved quality of the final product can have far-reaching financial implications. Minimizing the need for rework, scrap, or product recalls can lead to substantial cost savings and a better bottom line for the business.

Applications and Industries that Benefit from SiC Crucibles

The corrosion-resistant and high-performance properties of SiC crucibles make them a versatile solution for a wide range of industries and applications. Some of the key sectors that can benefit from the use of SiC crucibles include:

1. Metals and Alloy Melting: SiC crucibles are well-suited for melting a variety of metals and alloys, including aluminum, copper, brass, and stainless steel, due to their exceptional resistance to high temperatures and molten metal corrosion.

2. Glass and Ceramic Manufacturing: The thermal shock resistance and chemical inertness of SiC crucibles make them ideal for melting and processing glass, ceramics, and other high-temperature materials.

3. Electronics and Semiconductor Industry: The purity and contamination-resistant nature of SiC crucibles are crucial in the production of electronic components, semiconductors, and other high-tech products that require the utmost material quality.

4. Aerospace and Defense: SiC crucibles are commonly used in the production of specialized alloys and advanced materials for the aerospace and defense industries, where reliability, performance, and safety are paramount.

5. Medical Device Manufacturing: The corrosion resistance and purity of SiC crucibles are essential in the production of medical devices, implants, and other healthcare-related products that require strict quality control and material integrity.

6. Jewelry and Precious Metals: SiC crucibles are well-suited for melting and casting precious metals, such as gold, silver, and platinum, without the risk of contamination or degradation.

Across these diverse industries, the benefits of using a corrosion-resistant SiC crucible – including enhanced durability, improved melting efficiency, reduced contamination, and cost savings – make it a compelling choice for companies seeking to optimize their melting operations and maintain the highest product quality.

Choosing the Right SiC Crucible for Your Melting Needs

When selecting a SiC crucible for your specific melting requirements, it is essential to consider several key factors to ensure that you choose the right solution for your needs.

First and foremost, it is crucial to carefully assess the characteristics of the materials you will be melting, including their chemical composition, melting point, and any potential corrosive properties. This information will help you determine the appropriate grade and composition of the SiC crucible that can withstand the harsh operating conditions and provide the necessary level of corrosion resistance.

Additionally, the size and shape of the crucible should be tailored to the specific requirements of your melting process and the volume of material you need to handle. SiC crucibles are available in a wide range of sizes and geometries, allowing you to select the most suitable option for your production needs.

SiC るつぼを選択する際に考慮すべきその他の重要な点としては、製造プロセス、品質管理対策、サプライヤーの評判と専門知識などがあります。評判の良いメーカーの高品質でよく設計された SiC るつぼを選択すると、必要なパフォーマンスと利点を実現する耐久性、信頼性、一貫性のある製品を確実に手に入れることができます。

結論

結論として、耐腐食性 SiC るつぼの使用は、さまざまな材料の溶解と処理を必要とする業界にとって、画期的な出来事となる可能性があります。SiC るつぼは、優れた耐久性、溶解効率の向上、汚染リスクの低減、長期的なコスト削減を実現し、さまざまな産業用途にとって非常に魅力的なソリューションとなっています。

SiC るつぼに投資することで、企業は溶解作業を最適化し、製品の品質を向上させ、市場における全体的な競争力を高めることができます。高性能で持続可能かつコスト効率の高い溶解ソリューションの需要が高まり続けるにつれて、SiC るつぼの採用はさまざまな業界でますます広まっていくでしょう。

金属、合金、セラミック、特殊材料のいずれを扱う場合でも、耐腐食性 SiC るつぼは、溶解プロセスを新たなレベルに引き上げるために必要な信頼性と効率性を提供します。この革新的なテクノロジーの利点を活用して、産業オペレーションの可能性を最大限に引き出してください。