よくある質問

当社はアルミナ、ジルコニア、炭化ケイ素、窒化ケイ素、窒化アルミニウム、石英セラミックスなどの先進的なセラミック材料に主に焦点を当てていますが、常に新しい材料と技術を模索しています。特定の材料要件がある場合は、当社までご連絡ください。お客様のニーズを満たすか、適切なパートナーを見つけるために最善を尽くします。

絶対に。当社の技術チームはセラミック材料に関する深い知識と製品設計における豊富な経験を持っています。お客様の製品の最適なパフォーマンスを確保するために、材料選択のアドバイスと製品設計のサポートを喜んで提供させていただきます

当社には固定の最低注文金額要件はありません。私たちは常にお客様のニーズを満たすことに重点を置き、注文の規模に関係なく、高品質のサービスと製品を提供するよう努めています

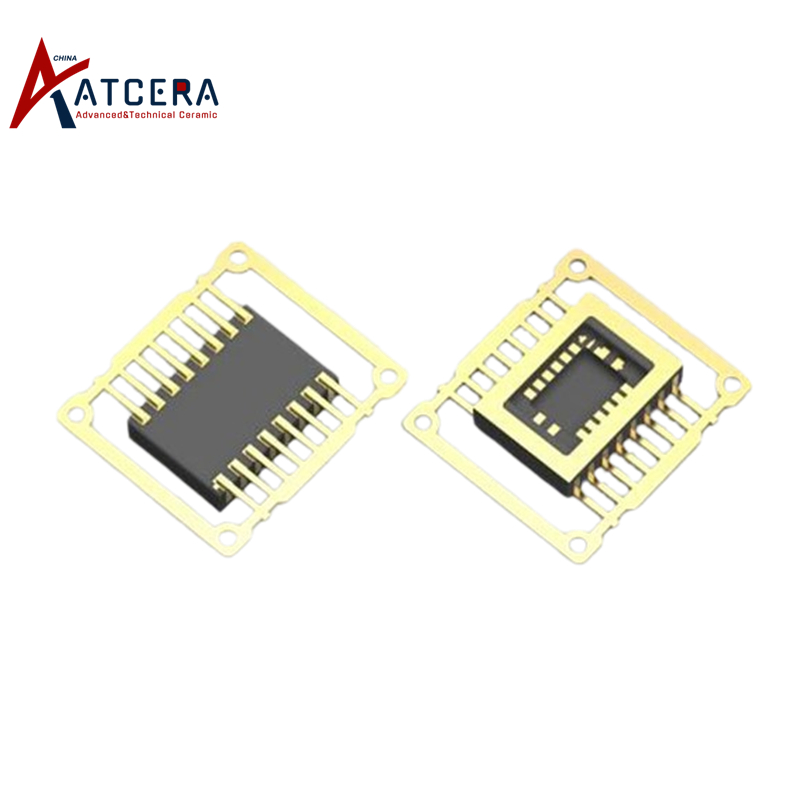

セラミック製品に加えて、当社は以下のような追加サービスも提供します。お客様のニーズに基づいて、お客様自身で製造したブランクまたは半完成ブランクを使用したカスタマイズされたセラミック加工サービス。外部委託のセラミックパッケージングおよびメタライゼーションサービスにご興味がございましたら、詳細についてお問い合わせください。当社は、お客様のさまざまなニーズを満たすワンストップ ソリューションを提供することに常に取り組んでいます。

はい、そうです。世界中のどこにお住まいであっても、ご注文の商品を安全かつタイムリーにお届けいたします。